In 1982, the 1st power generating unit of the ChNPP (1ChNPP) was undergoing intermediate planed maintenance (IPM) that was supposed to be completed on September 13. On September 8, all the main repair jobs were finished, and a test run of the reactor began. The accident seems to have occurred on September 9, some time between 05:00 p.m. and 06:00 p.m. The reactor had (heating) capacity of 700 MW, and its turbine generator was started up. Besides, at that time the Adjustment and Ttesting Shop (ATS) did not complete their work yet; they were adjusting flow rates in each channel.

For some reason (let’s say ‘unknown reason’ for the time being), one of the fuel channels was destroyed (No. 62-44), and the mixture of water and steam (under pressure of 7 Pa) started penetrating through the resulting longitudinal rupture and washing out graphite stack; the mixture was carrying along fuel from the destroyed fuel assembly (together with all radioactive crud that had accumulated there). Neither the Senior Reactor Control Engineer (SRCE), nor any one else at the unit understood the situation at once, and went on working under load just as before, waiting for the situation to become clear. It was only 20 (or even 30) minutes later that they realized it was impossible to continue working like that, and the reactor was damped.

As a result of such work, the core around the destroyed channel (and inside it) was seriously damaged, and repair of the damage turned into a very dirty (from the radiation point of view), hard and lengthy job. It took almost a year to fully eliminate consequences of that accident, and the core area adjacent to the destroyed channel was put off service forever, a kind of an eyesore for the SRCE.

Now, a question arises: why was the channel destroyed, and what was the primary reason? The obvious reason is always the same: burnout and destruction of fuel elements followed by channel destruction. But what is the reason of fuel element burnout, then?

Principally, there may be two different and, to a certain extent, contradictory options.

1) There was a local outburst of energy release, just as during the 1975 accident at the LNPP, or the 1986 accident in Chernobyl.

2) Water flow was stopped through the channel, just as it in 1986, according to the Chief Designer.

You don’t have to be a Solomon to understand which of these options was selected by the accident investigation board. According to the first option, the reactor design and physical properties were faulty; besides, they would have to find out what had been happening in the Control Room of Unit (CRU) at that time, and why the reactor faults had shown themselves. According to the second option, there was nothing to find out, and the culprit was obvious - the ATS engineer: he had been adjusting flow rates, and stopped water access into the channel.

Unlike the 1986 Chernobyl accident, we have no documentary sources about this case in order to understand ourselves clearly what actually happened then. We can only use evidence provided by eyewitnesses of these events, and also the book written by the Chief Designer. Here’s what his book says ([E2] page 595):

«During investigation of the accident causes it was established that in order to maintain average flow rate of heat carrier, it had been necessary to open an stop & adjusting valve (SAV) in Channel 62-44. The servicemen thought the valve was faulty and eliminated the fault, contrary to the safety regulations. The valve was closed completely, and then opened, which resulted in stopping water supply into the Channel with power of 450 kW…»

Almost the same is said (during conversation) by near witnesses that worked as backup SRCE’s (but not on that shift). Here are the words of one of them at the forum of the web-site pripyat.com:

«A Mr.L., the ATS engineer, just instructed the operator of CH{Central Hall},Mr.S., to close the SAV- allegedly, to check the guide plate. That was done, only it turned out the plate was not in position.

At that time the 308 rooms were not locked yet, and the CH operator handled the SAV himself, without [SIM] (Shift Mechanic Engineer), or the Reactor Shop Shift Manager (RSSM). »

The guide plate is a limiting element that prevents the valve from closing completely.

And that would be the end of story – except that there are a few suspicious details.

1) Both the Chief Designer and the SRCE describe a situation that is, as a matter of fact, absolutely unrealistic. The reactor is running with the power of 700 MW, and the servicemen at the same time are turning the SAV (changing flow rates via the reactor channels). Note that the servicemen are doing this without approval of, and even without informing the reactor operators, and by doing so, they almost intentionally stop water supply into one of the channels.

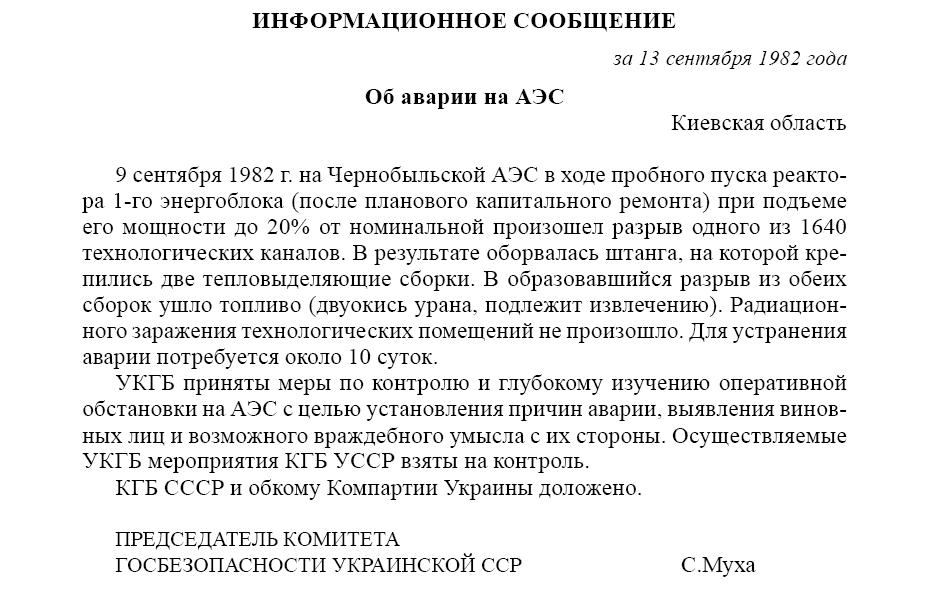

2) The Ukrainian division of the KGB (UKGB) that has been watching this accident very closely from the very first day, overlooks, for some reason, such criminal actions. And there are no versions regarding any sabotage or even gross negligence. Here’s the description of the accident according to the UKGB ([EV], Document No.11 ) (this memorandum was submitted to the Central Committee of the Ukrainian Communist Party):

3) For some reason, not a word is said what the SRCE was doing during this flow rate adjustment, and, generally, what was happening in the CRU. The question arises, how it could so happen that they failed to notice stopping water supply into the channel, and why lots of warning signals and alarms generated when the accident began were ignored for half an hour.

4) The senior officers of the ChNPP involved in the analysis of the 1986 accident - A.S.Dyatlov and N.V.Karpan – are very cautious about the 1982 accident. They do not object directly to the above version, but at the same time, they do not seem to fully agree with it. Here’s what N.V.Karpan says ([K2] page 300):

«As an eyewitness of this accident and one of those involved in elimination of its consequences, I don’t have much to add –the version of NIKIET {Scientific R&D Institute for Power Technology} that blamed the Chernobyl ATS engineer for stopping completely water supply into the Channel 62-44 has never grown into anything else but a version. Both the foreman and the whole team of servicemen that carried out flow rate adjustment that day have been repeatedly denying the error inflicted upon them. On that day they worked in the usual way, in strict compliance with the regulations, according to which that a guide plate was to be installed on the regulator that would mechanically prevent complete stopping of water supply into the channel.»

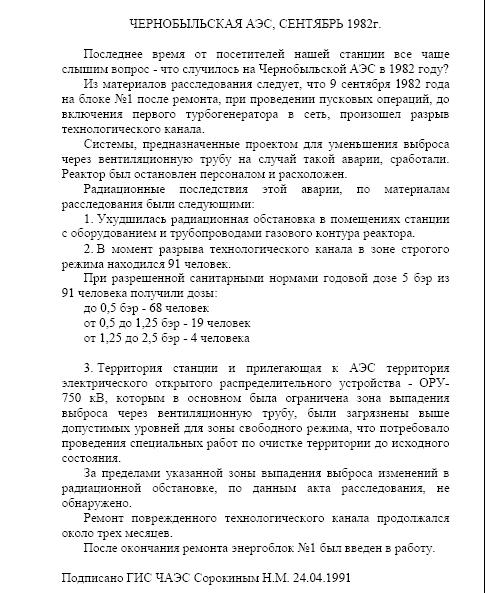

And here’s the official statement of the NPP management:

5) Note how accurately the Chief Designer describes his version of the accident, and how lenient he sounds regarding the actions taken by the servicemen – as a matter of fact, they were criminal actions. Compare this to the way he will later on describe erroneous actions of the operating staff in 1986. Apparently, in this case, he was very much unwilling to start any criminal investigation, let alone any court proceedings. This is not a political case (as it will be in 1986), and there’s no way he could really influence the investigators and the court. What if they would really want to find the truth?

6) The Research Supervisor that would always side with the Chief Designer, this time, for some reason, started an investigation of his own. As a result, and without any discussion, he brought forward another (third) version regarding the culprit of the accident – it was the manufacturer of the channel pipes. (see [K2] page 299):

«It turned out that the zirconium channel pipes were destroyed due to residual internal stress in their walls. The manufacturing plant had on its own initiative changed the production process of channel pipes, and this ‘novelty’ resulted in the accident in the reactor of the 1st PGU of the ChNPP causing deformation of the core graphite stack.»

----------------------------------------------------------

|